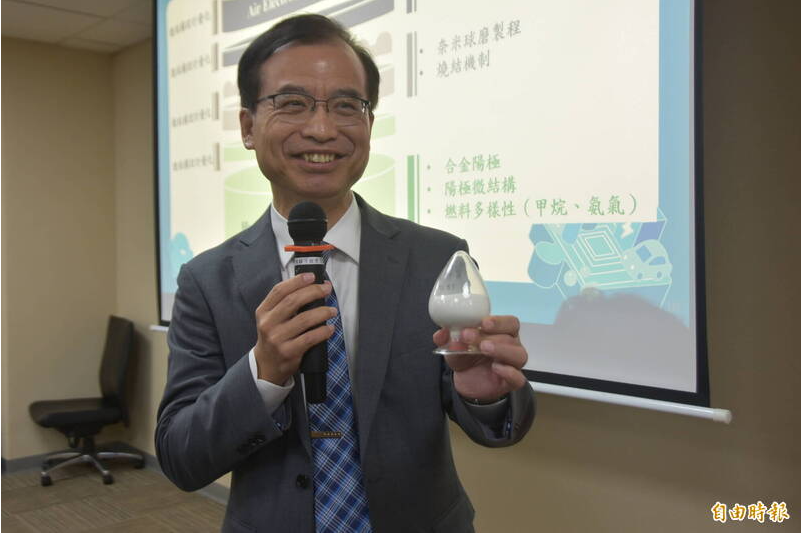

Amid the global push toward net-zero carbon emissions, hydrogen production has emerged as one of the most critical energy technologies. With funding from the National Science and Technology Council (NSTC), a research team led by Professor Chung-Jen Tseng of National Central University (NCU), together with several academic collaborators, has achieved a major breakthrough in proton-conducting solid oxide electrolysis (P-SOEL) technology. By overcoming key challenges in core materials and microstructural design, the team has developed highly stable and durable electrodes and electrolytes. Their system requires only about 3.8 kWh of electricity to produce one cubic meter of hydrogen, placing its performance among the world’s leading technologies.

Water electrolysis produces hydrogen and oxygen by splitting water using electricity. Professor Tseng, Director of the Hydrogen Energy Research Center at NCU, emphasized that hydrogen is a vital energy carrier in the transition to net-zero emissions. When produced using renewable electricity—such as solar or wind power—hydrogen generation results in zero carbon emissions. The hydrogen can then be applied in transportation, internal combustion engines, or fuel cells. However, conventional electrolysis systems rely on liquid electrolytes, which are alkaline, corrosive, and pose safety risks such as flammability. These limitations have driven researchers to explore solid oxide electrolysis technologies.

Professor Tseng explained that while solid oxide electrolytes avoid many issues associated with liquid electrolytes, they traditionally require ceramic materials and operating temperatures exceeding 800°C. Such extreme conditions severely limit material choices for surrounding components, necessitating expensive alloys and resulting in high system costs.

To address these challenges, Professor Tseng collaborated with Professor Sheng-Wei Lee from NCU’s Institute of Materials Science and Engineering, Professor Yi-Ming Hung from the Department of Chemical and Materials Engineering at Yuan Ze University, and Research Fellow Tzu-Yuan Chen from Academia Sinica. Together, they successfully developed key materials for proton-conducting solid oxide electrolysis (P-SOEL), including compounds such as BCZY and PBSCF, used as porous interlayers and electrode oxides. By optimizing three-dimensional microstructures and employing nano-ball milling techniques, the team significantly enhanced material performance.

The resulting solid-state electrochemical cell demonstrated excellent proton conductivity at temperatures as low as 600°C, while substantially reducing interfacial resistance and improving overall efficiency.

In terms of performance, Professor Tseng noted that under operating conditions of 650°C and 1.6 V, the P-SOEL system achieved an exceptionally high current density of 5.568 A/cm². The electrical energy required to produce one cubic meter of hydrogen was reduced to 3.83 kWh, lower than the 4–5 kWh typically required by conventional liquid-electrolyte systems. This level of performance places the technology firmly among the international research leaders in the field. The team’s findings have been reported in journals such as the International Journal of Hydrogen Energy and Electric Power Systems Research.

Professor Lee highlighted that lowering the operating temperature of solid-state hydrogen production systems improves thermal management and overall energy efficiency. Professor Hung emphasized that reducing the use of rare-earth elements while maintaining high performance remains a key focus of the team’s ongoing research. Research Fellow Chen added that nano-engineering enables ultra-thin materials to remain electrochemically active, significantly reducing material costs.

Professor Tseng concluded that the team has already fabricated a button-sized solid-state fuel cell using the P-SOEL technology. The next stage will involve scaling up to 5 cm² cells and progressively stacking them, paving the way toward commercial deployment. Notably, Delta Electronics has expressed interest in the technology, signaling strong potential for industrial application.